Solutions

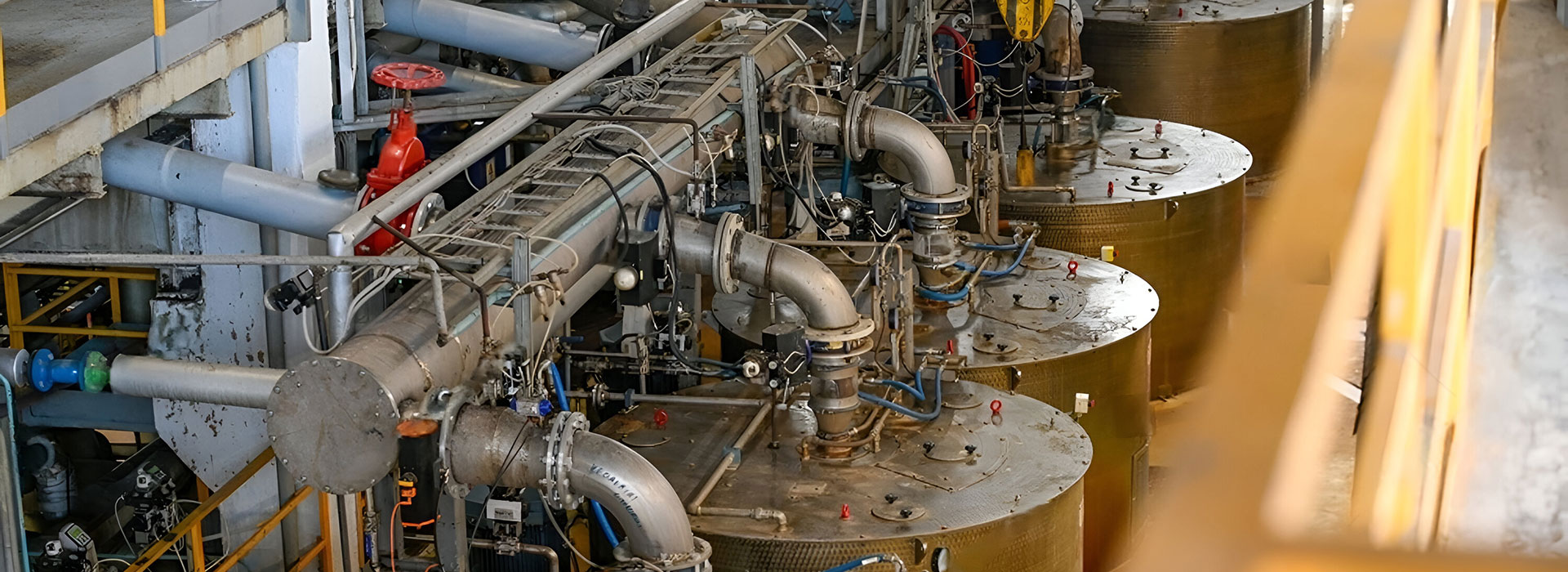

Fuel Systems

Enhance Fuel Efficiency

Discover top-notch solutions and precision engineering for enhanced system efficiency.

Inspection

Each fuel injector is visually inspected for physical damage and signs of wear. This includes checking for leaks, cracks, or other visible issues.

Cleaning

The fuel injectors are cleaned using specialized equipment and solvents to remove deposits, varnish, and carbon buildup. This process helps restore the flow and spray pattern of the injectors.

Inspection

Each fuel injector is visually inspected for physical damage and signs of wear. This includes checking for leaks, cracks, or other visible issues.

Cleaning

The fuel injectors are cleaned using specialized equipment and solvents to remove deposits, varnish, and carbon buildup. This process helps restore the flow and spray pattern of the injectors.

Flow Testing

After cleaning, the injectors are subjected to flow testing to assess their fuel delivery performance. This involves measuring the fuel flow rate and spray pattern to ensure consistency across all injectors.

Pressure Testing

The fuel injectors undergo pressure testing to determine if they are capable of operating within the specified pressure range. This helps identify any potential leaks or issues with injector seals or O-rings.

Replacement of Components

If necessary, worn or damaged components such as O-rings, seals are replaced with new ones to ensure proper functioning of the fuel injectors.

Final Inspection and Reassembly

The injectors are inspected once again after cleaning and testing to ensure they meet quality standards. They are then reassembled with any replaced components.

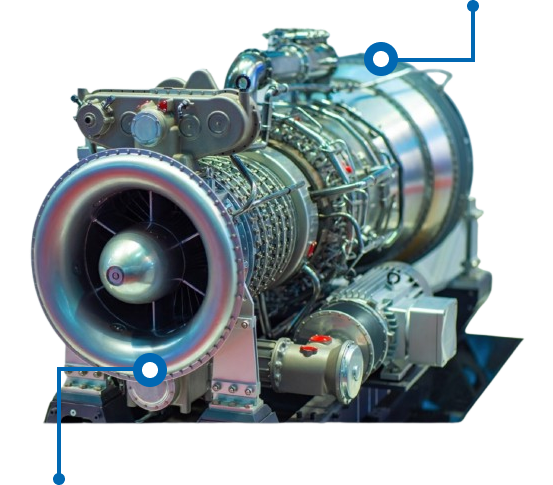

Tru-Marine delivers integrated MRO services for Turbochargers, Governors, Fuel Systems, and Engines, covering overhauls, reconditioning, emergency repairs, and spare parts supply.