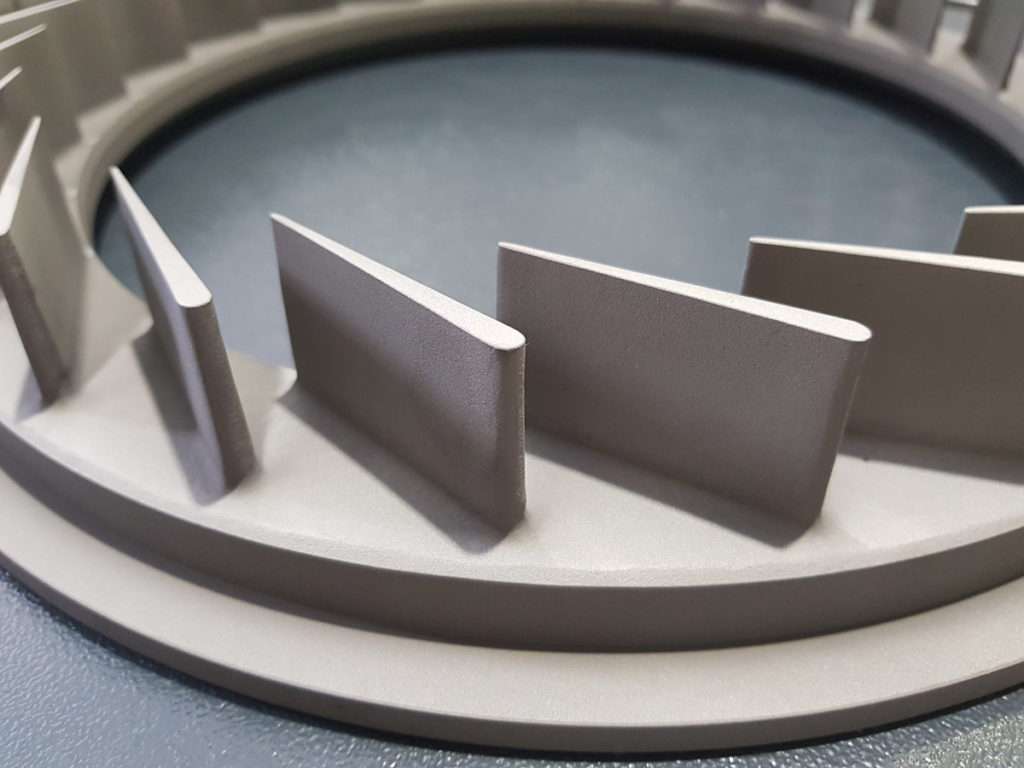

Leveraging on High Velocity Oxygen Fuel (HVOF), Tru-Marine has launched its TM Supercoat method to offer significant protection to component erosion and wear.

- Molten or semi-molten coating materials are sprayed onto the surface of the nozzle ring with a high-temperature- high-velocity gas stream

- Resultant spray coating has exceptional hardness and outstanding adhesion to the substrate material, providing substantial wear resistance and improved corrosion protection due to less through porosity

- Higher impact velocities and smaller powder sizes produce smoother as-sprayed surface, and the resulting dense spray coating can be ground to a very high surface finish

About Tru-Marine’s Innovative Technology

Tru-Marine has been at the forefront of innovative technology to develop relevant reclamation solutions for the economic recovery of worn turbochargers. The company’s R&D capabilities date back to over two decades, where it first collaborated with research and tertiary institutions to develop the welding repair of turbine blades using gas tungsten arc process. Over the years, Tru-Marine has established progressive in-house R&D efforts to extend its product and service lines using indigenous technologies. It has a strong reputation for bringing about disruptive technology that proactively phases out market practices that have become sub-optimal in productivity and relevance.