Why Turbocharger Nozzle Rings Should Be Upgraded with Tru-Marine’s Supercoating Technology

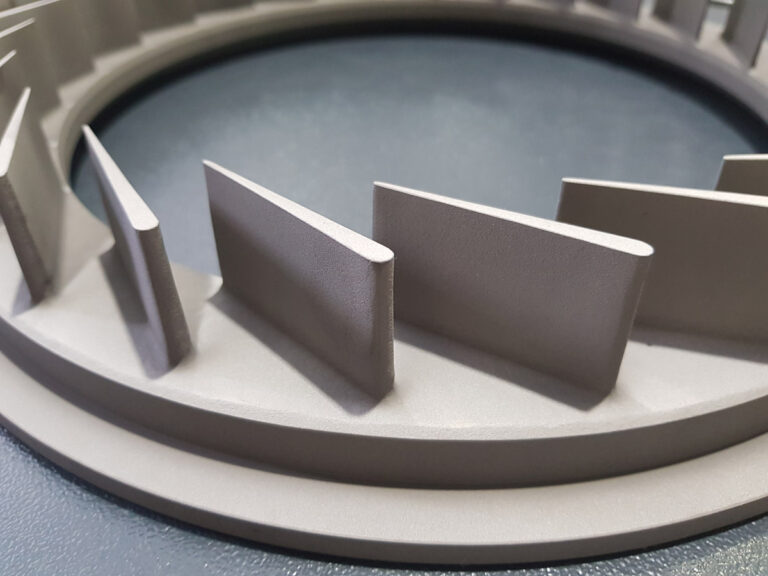

Turbochargers are critical in optimizing engine performance, whether on marine vessels or in industrial and land-based operations like power generation and heavy machinery. One of the most important components in a turbocharger is the nozzle ring, which directs exhaust gases onto the turbine wheel, ensuring efficient operation. However, nozzle rings endure extreme conditions—high temperatures, corrosion, and wear—that can degrade their performance over time.

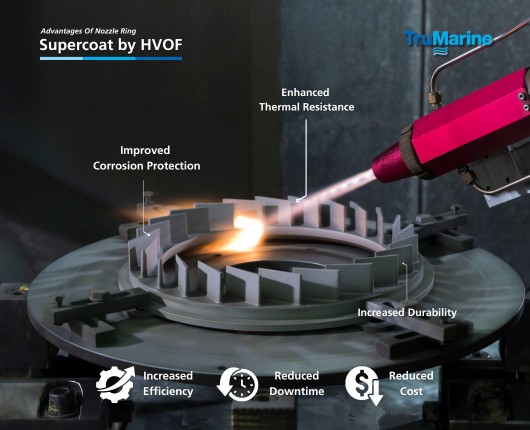

To meet these challenges, Tru-Marine’s Supercoat by HVOF (High-Velocity Oxygen Fuel), also known as TM Supercoat, offers an advanced solution that significantly improves the durability, efficiency, and longevity of nozzle rings, benefiting both marine and industrial turbochargers alike.

1. Enhanced Thermal Resistance

Turbochargers in marine and industrial environments operate under extreme temperatures, which can cause the nozzle rings to weaken or deform.

With TM Supercoat, nozzle rings gain improved thermal resistance, allowing them to withstand higher temperatures for longer periods without losing structural integrity. This upgrade ensures sustained performance in the face of the high thermal loads typical of marine engines and heavy industrial equipment.

Improved Corrosion Protection

Corroded nozzle ring after long exposure in marine conditions

Marine turbochargers are constantly exposed to corrosive environments, but industrial turbochargers are not immune to corrosion either—chemical exposure and moisture in many industrial settings can degrade components. TM Supercoat adds a robust protective layer that shields nozzle rings from corrosion. This protection is crucial in both marine and industrial contexts, where equipment failure due to corrosion can lead to costly repairs and downtime.

2. Increased Durability

The nozzle ring’s position within the turbocharger exposes it to mechanical wear from high-velocity gas flows and particulates. Without adequate protection, this wear can shorten the nozzle ring’s lifespan and reduce turbocharger efficiency. TM Supercoat increases the wear resistance of nozzle rings, making them significantly more durable. This results in a longer operational life for turbochargers, whether they’re used in ships or in industrial equipment such as turbines or generators.

3. Reduced Downtime and Costs

When nozzle rings degrade, turbochargers become less efficient and may require frequent maintenance or early replacement. For both marine vessels and industrial operations, downtime can be extremely expensive. Upgrading nozzle rings with TM Supercoat reduces the need for frequent repairs, minimizing unplanned downtime. With extended service intervals, operators save on both repair costs and the indirect costs of operational disruptions.

4. Boosted Efficiency

Efficient turbocharger performance is vital for reducing fuel consumption, emissions, and operational costs. Nozzle rings that have been upgraded with TM Supercoat maintain optimal performance for a longer period, contributing to overall engine efficiency. Whether in a marine environment, where fuel efficiency is critical, or in industrial settings requiring continuous operation, the enhanced performance provided by our supercoating translates into tangible operational benefits.

5. Future-Proofing Your Equipment

As environmental regulations tighten and industries demand greater efficiency, having components that can meet these challenges is essential. TM Supercoat not only upgrades the current performance of nozzle rings but also prepares your turbochargers for future demands. By enhancing the resilience and efficiency of this critical component, you can extend the life of your equipment and delay the need for costly overhauls or replacements, making it a forward-thinking investment.

TM Supercoat Technology

Upgrading turbocharger nozzle rings with TM Supercoat provides tangible benefits for marine, industrial, and land-based turbochargers. Enhanced thermal resistance, improved corrosion protection, and increased durability all contribute to longer-lasting, more efficient turbocharger performance. With reduced downtime, lower maintenance costs, and improved efficiency, this upgrade is a smart investment for operations that rely on turbochargers to maintain productivity.

Whether you’re managing a fleet of vessels or overseeing industrial operations, choosing TM Supercoat for your turbocharger nozzle rings will keep your engines running smoothly, reliably, and efficiently—today and well into the future.

Tru-Marine has over 47 years of experience in turbocharger maintenance and is equipped to handle both marine and land-based turbochargers. Our global network of service stations—strategically located in Singapore, Rotterdam, Shanghai, Zhoushan, Tianjin, Weihai, Guangzhou, Rotterdam and Dubai ensures that your turbochargers are maintained to the highest standards, whether on sea or land. We offer integrated services covering turbochargers, governors, fuel systems, and engines to support all operational needs.

Get in Touch 24/7

Phone: +65 6861 8398

Email: turbo@trumarine.com